Introduction

This article provides details on how to use BusinessCraft to address Service Exchange processing requirements. As Service Exchange environments quite often require items to be Serial and/or Warranty tracked, these topics are also covered in this document.

The scenario used for this document is as follows:

New items are purchased into stock

Customer requests a new item to be supplied on a Service Exchange basis

New item is supplied to customer subject to return of item being service exchanged

Service Exchange item is received back from customer

Repairs are carried out to make Service Exchanged item as new

Customer is invoiced the repair costs plus relevant margins and handling fees

Setup

Inventory Module Setup

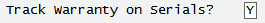

Go to Inventory > Setup > Inventory Setup > Page 2 and ensure that the “Track Warranty on Serials” field is set to Y. This enables streamlined Warranty Tracking of serial tracked items.

Warranty Tracking Module Setup

Navigate to Warranty Tracking > Setup > Warranty Setup and if Warranty Tracking has not been used before the system will create a control record for the module. Click OK and exit. Please refer to the Warranty Tracking Product Guide for further details on setup fields if required.

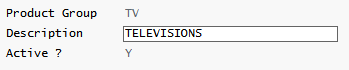

Product Groups

Go to Inventory > Tables > Product Groups and ensure that there are suitable Product Groups (optional) for the items subject to Service Exchange. For more details on Product Groups refer to the Inventory Product Guide. Here is an example Product Group:

Product Categories

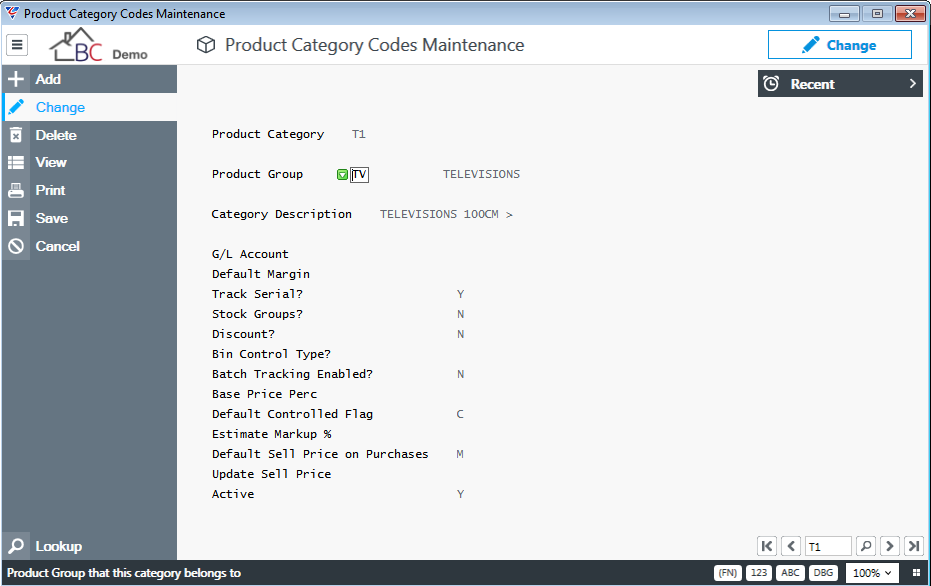

Go to Inventory > Tables > Product Categories and ensure that there are suitable Product Categories for the items subject to Service Exchange. For more details on Product Categories refer to the Inventory Product Guide. Product Categories can be linked to Product Groups.

Please note that Serial Tracked items must belong to a Product Category that has the “Track Serial” field set to Y. As the Serial Tracking setting is at the Product Category level, this means that ALL items belonging to that Product Category will be serial tracked.

Here is an example of a Product Category where the items belonging to that category are serial tracked:

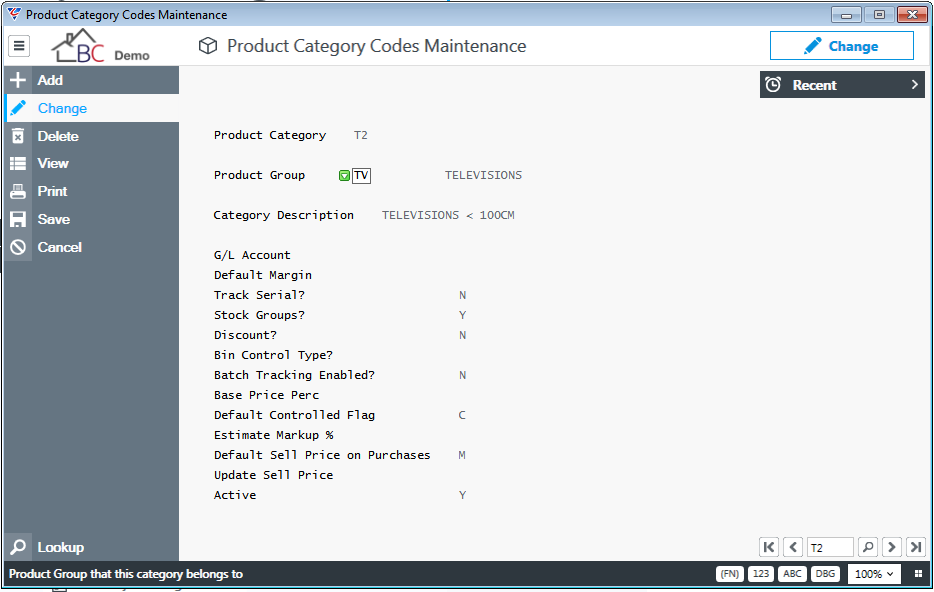

If there are items that normally belong to one Product Category but some are serial tracked and some are not, an additional Product Category is needed so that items to be serial tracked belong to one Product Category and items not serial tracked belong to a separate product category. Here is an example of a Product Category where the items belonging to that category are not serial tracked:

Note that both Product Categories belong to the one Product Group.

Items

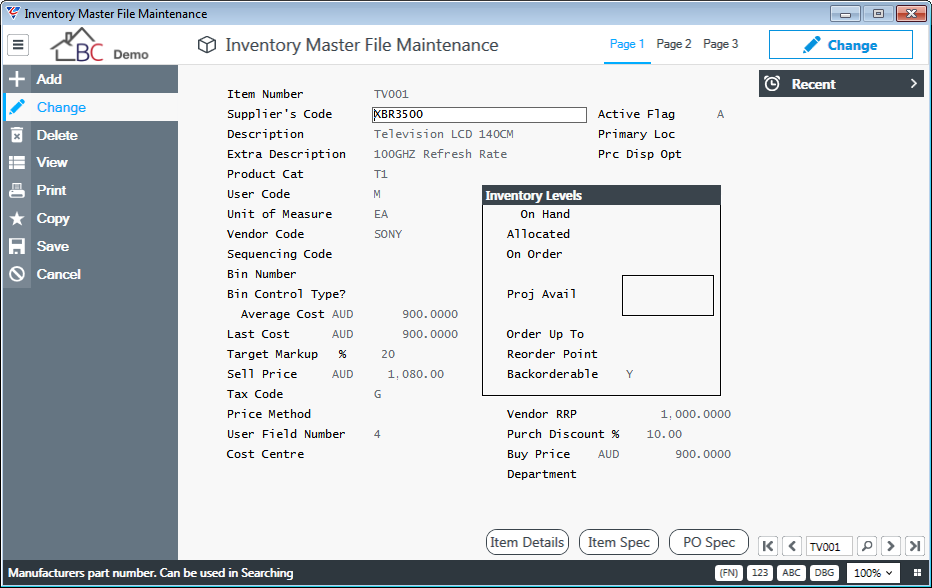

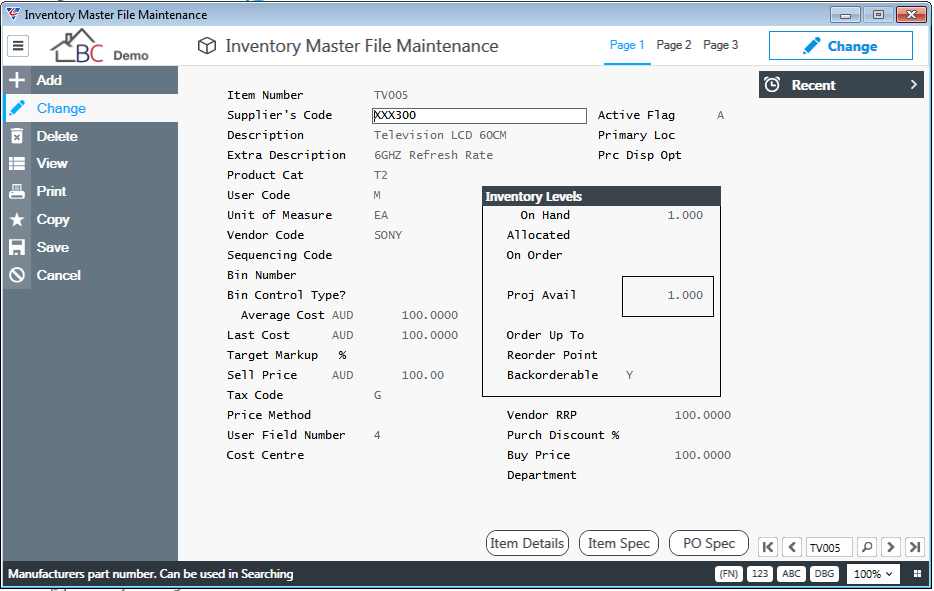

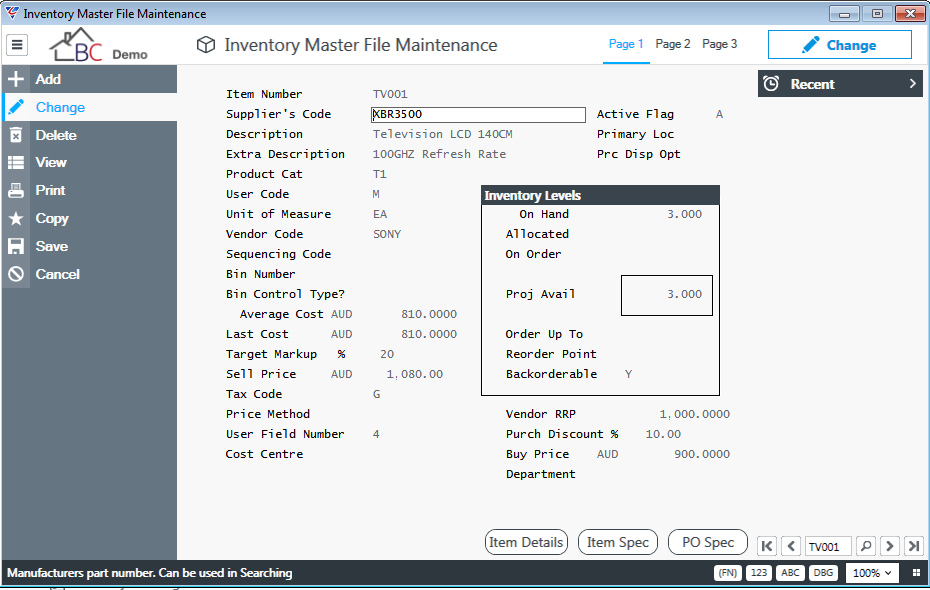

Go to Inventory > Maintain > Inventory and ensure that the required items are defined. Product Categories assigned to the items may need to be changed subject to any changes made to existing Product Categories as explained earlier in this document. Here is an example of an item that is linked to a serial tracked Product Category:

Here is an example of an item that is linked to a non-serial tracked Product Category:

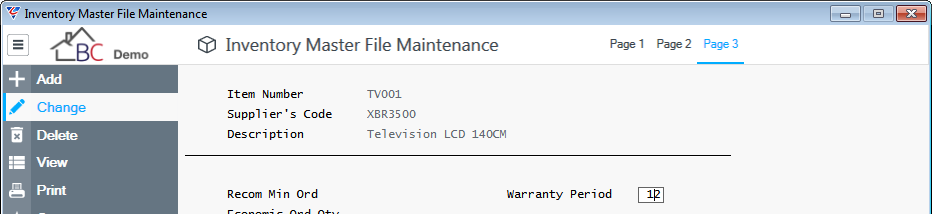

Warranty Period for Items

If Warranty is applicable to the items, go to Page 3 and fill in the Warranty Period field. Please note the value is in months:

Stocktake Serial Tracked Items

Where an item has been changed from belonging to a non-serial tracked product category to a serial tracked product category, it is essential to stocktake the item before commencing any transaction processing.

The reason for this is that when a serial tracked item is issued, a serial number from the list of serial numbers held in the system for that item must be selected. Clearly a non-serial tracked item will not have any serial numbers stored. When recording the count on a stocktake order for a serial tracked item a prompt requests the serial numbers for the item.

Processing

In the examples that follow, we use an item that is serial tracked and has a warranty so that the full range of possibilities is covered. Where the item being processed for Service Exchange is either not serial tracked and/or does not have a warranty, those portions of the process are not applicable.

Here is the scenario for the process used in the following examples:

New items are purchased into stock

Customer requests a new item to be supplied on a Service Exchange basis

New item is supplied to customer subject to return of item being service exchanged

Service Exchange item is received back from customer

Repairs are carried out to make Service Exchanged item as new

Customer is invoiced the repair costs plus relevant margins and handling fees

Purchasing

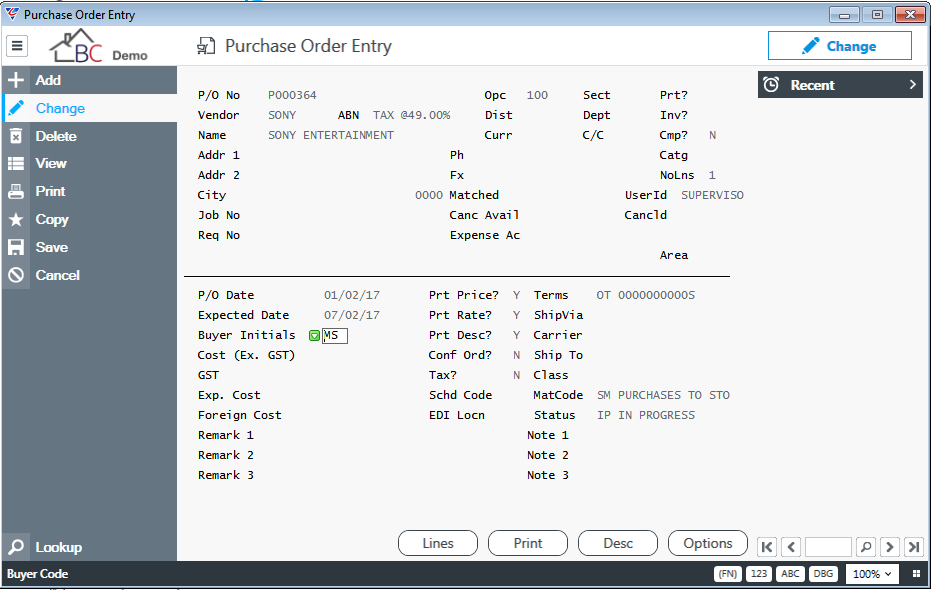

Raise a purchase order to purchase the items to stock. Go to Purchase Orders > Maintain > Purchase Orders. Please note the Purchase Order could have been generated from a requisition or back order. How the Purchase Order is created does not impact the process. Here is the Purchase Order Header:

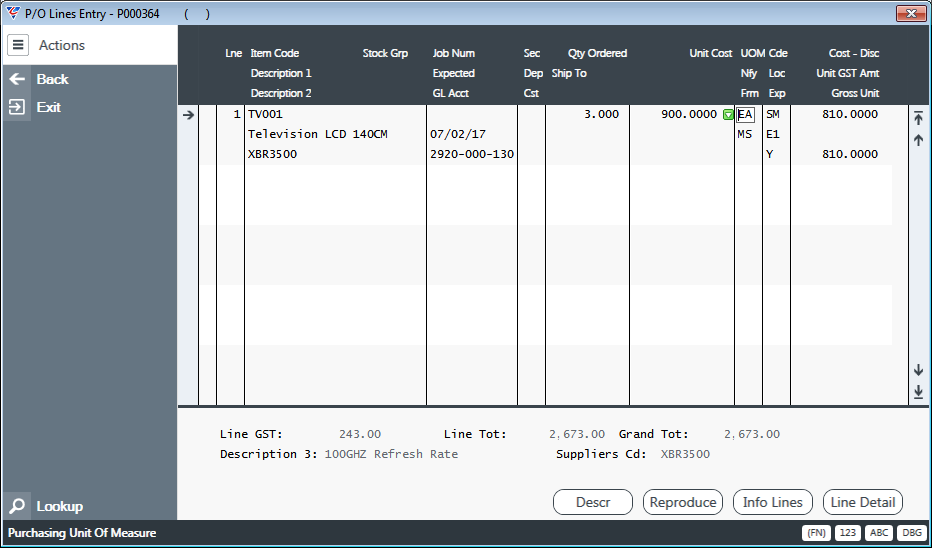

Activate the Lines (F5) function key and create the Purchase Order Lines for the items required:

Exit the Purchase Order Lines and Purchase Order screen.

Receiving

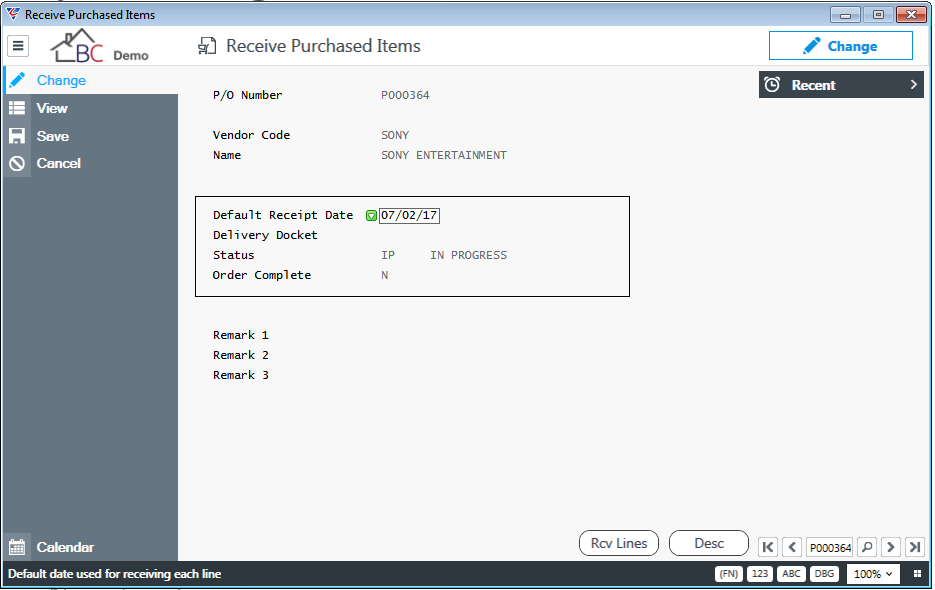

Receipt the goods into stock. Go to Purchase Orders > Transactions > Receipts :

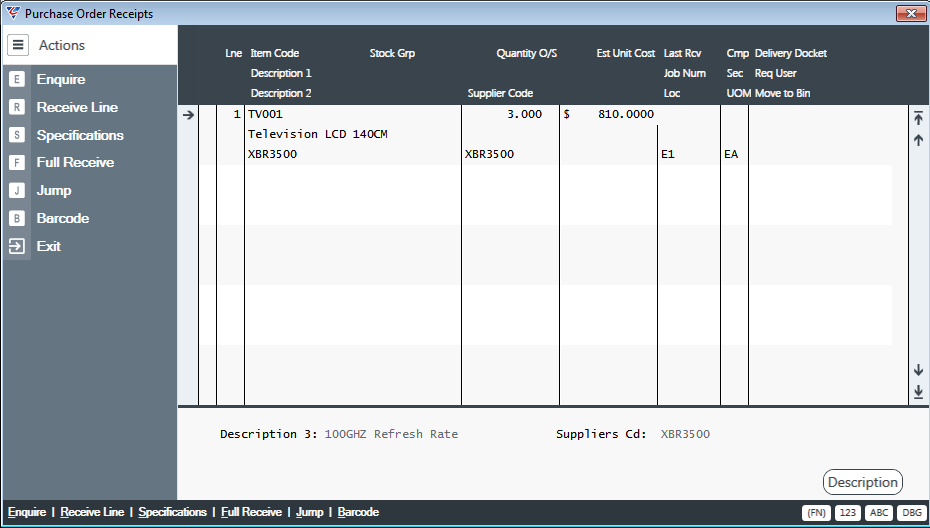

Activate the Rcv Lines (F5) to receive the items into stock:

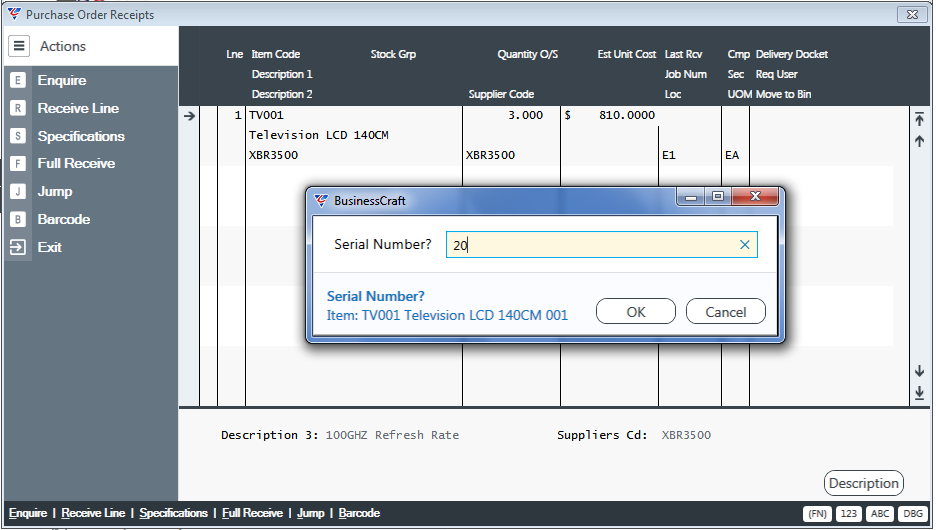

In this example, all three items were received, so click on Receive Line. It is at this point that the process will vary for serial tracked items. The system will pop up a Serial Number prompt. In this example the prompt will appear 3 times and serial numbers 20, 21, and 22 are entered :

On completion, exit the Purchase Order Receipt screens in the normal way.

Impact on Inventory

After completing the receipt, particularly for serial tracked items it is worth reviewing inventory to understand the impact. Go to Inventory > Maintain > Inventory and find the item just receipted:

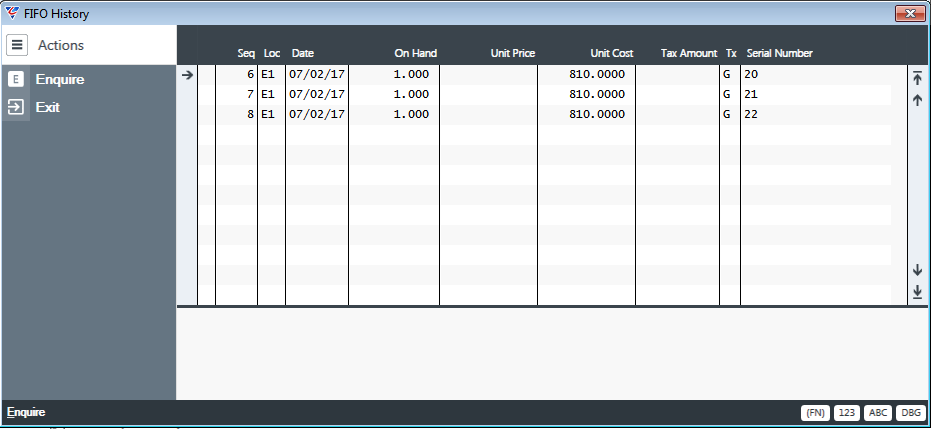

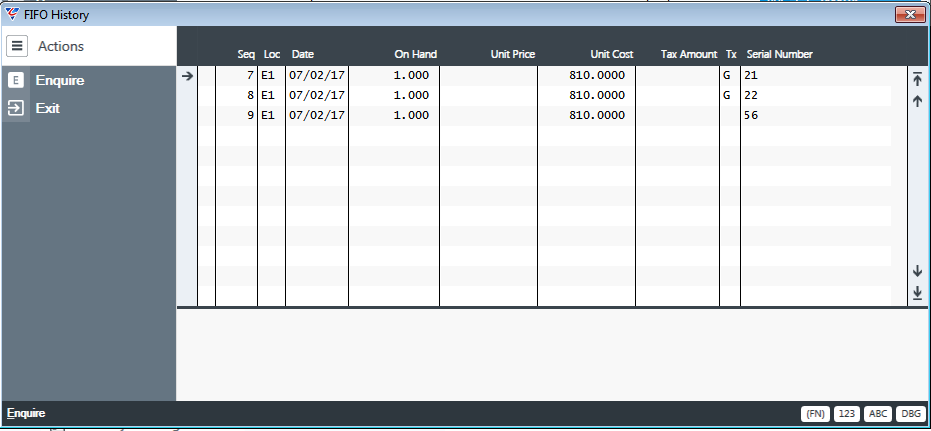

Activate the Item Details (F5) function key and select FIFO History from the Item Details Selection menu, which shows the serial numbers of the items received:

Impact on Warranty Tracking of Receipt

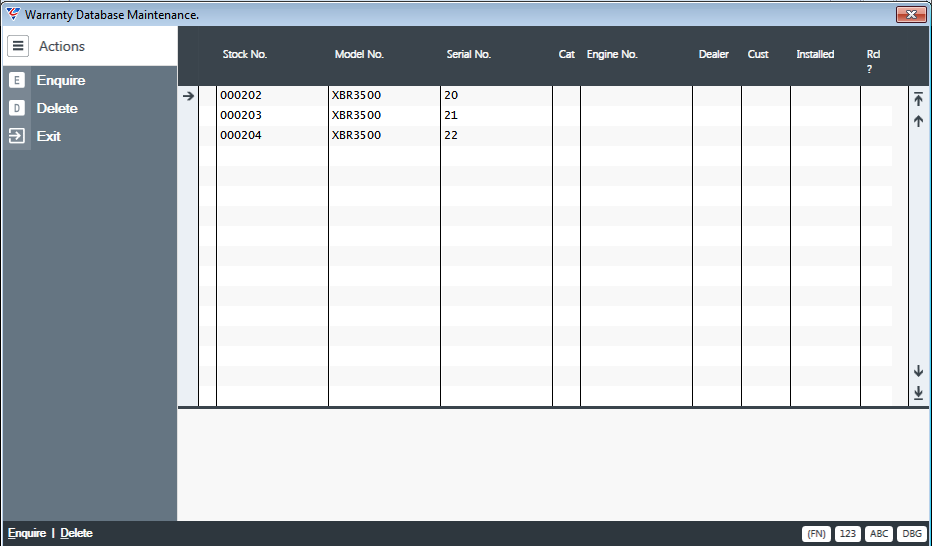

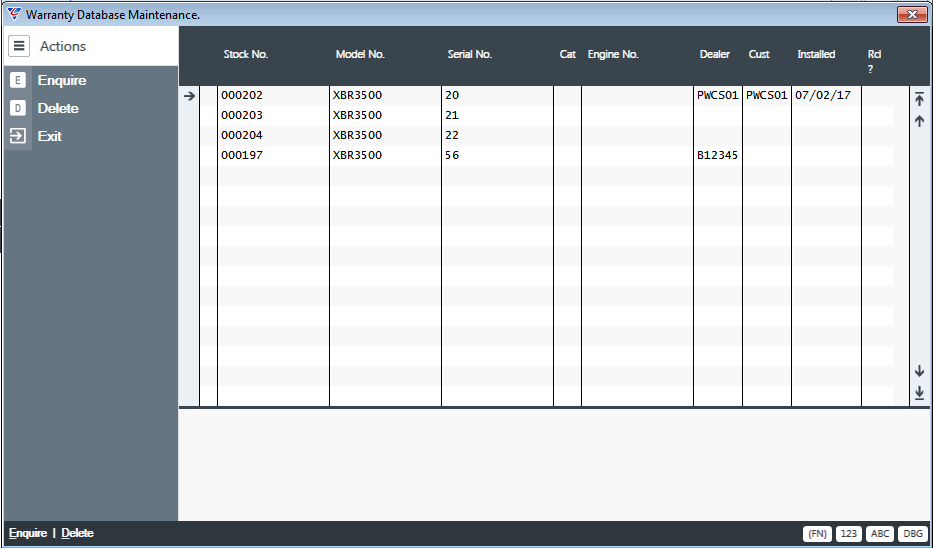

After completing the receipt, for serial tracked items, the system automatically creates Warranty Tracking records. Go to Warranty Tracking > Maintain > Warranty Maintenance, activate the View button from the Menu Sidebar, enter the item number range (and optionally the serial number range):

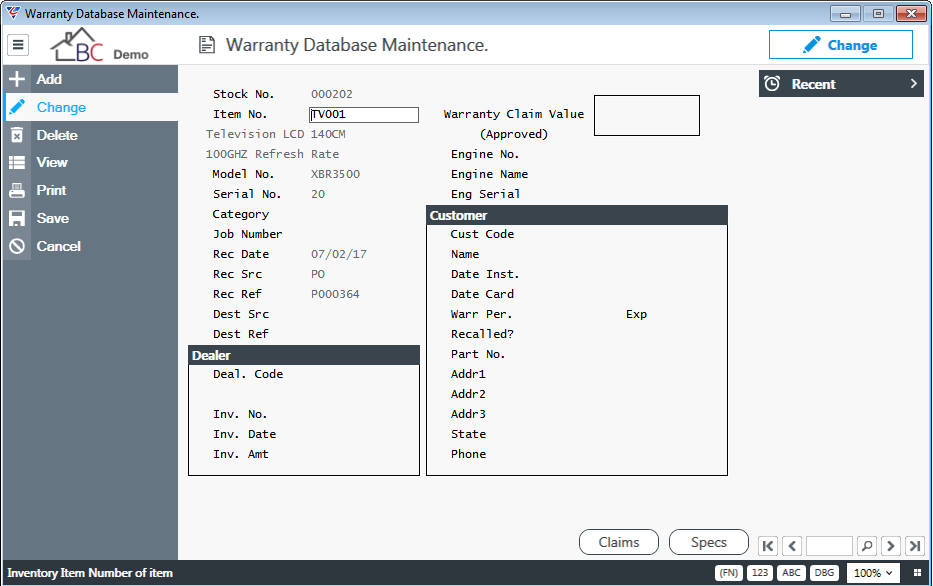

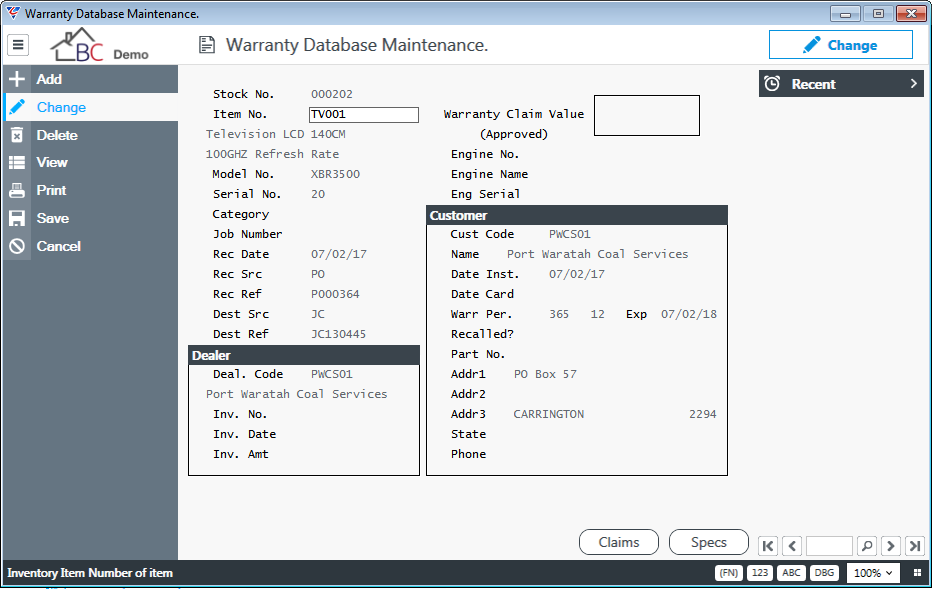

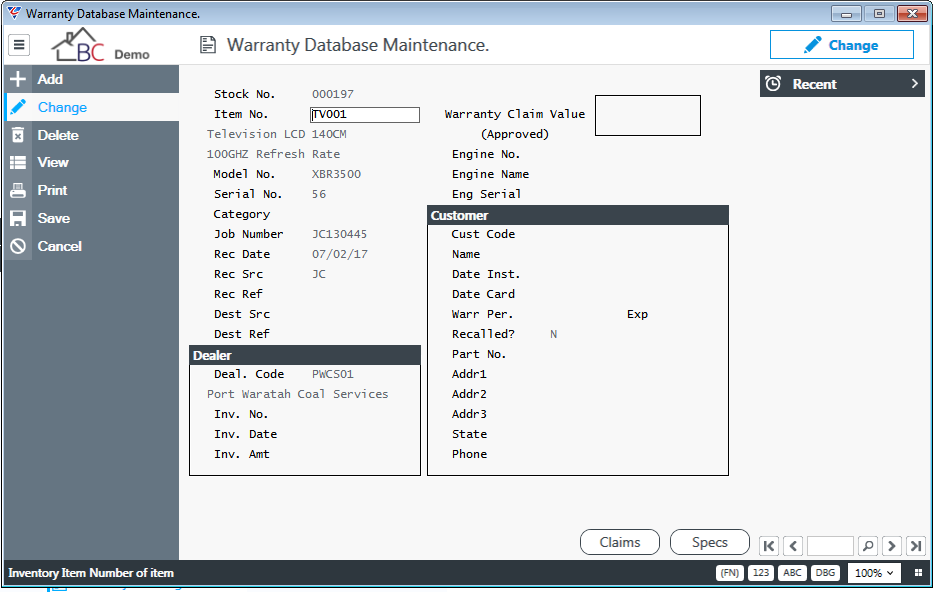

Enquire on one of the records to view the warranty record for the item, including the receipt date, receipt source and purchase order:

Service Exchange Request from Customer

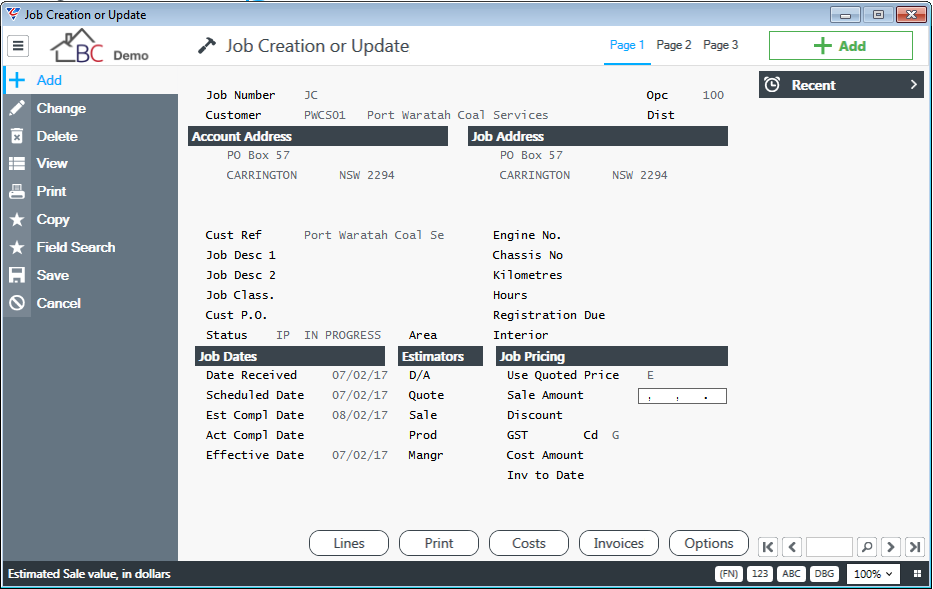

A customer advises that they have a TV001 item that they wish to send back for a Service Exchange. Go to Job Costing > Maintain > Jobs and create a Job:

Supply the Item to the Customer

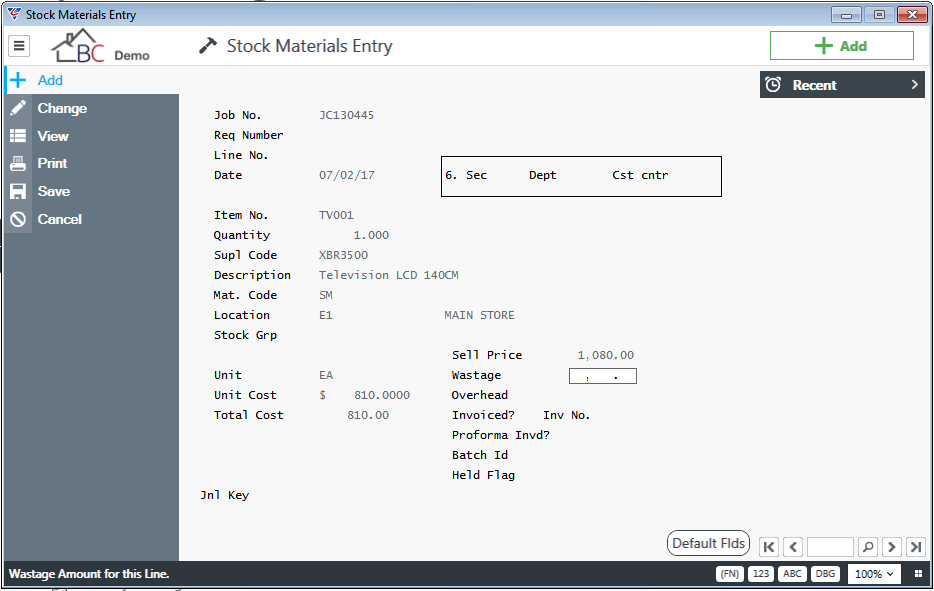

In this scenario, the service exchange item is supplied in advance of the item to be repaired being returned. Go to Job Costing > Transactions > Cost Entry > Job Materials Cost Entry:

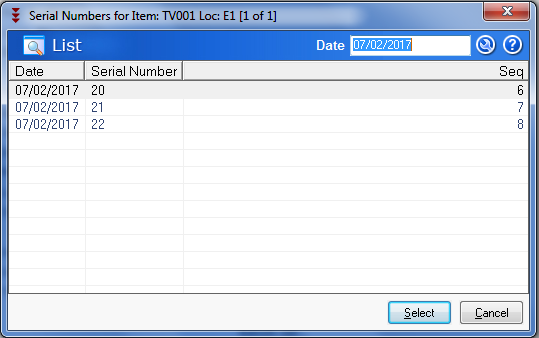

On save and exit, if the item is serial tracked, a prompt will appear to confirm from the existing serial number records in inventory which item is being supplied:

There will be costs on the job equivalent to the Weighted Average Cost of the item issued out of Inventory.

Impact on Warranty Tracking of the Material Issue

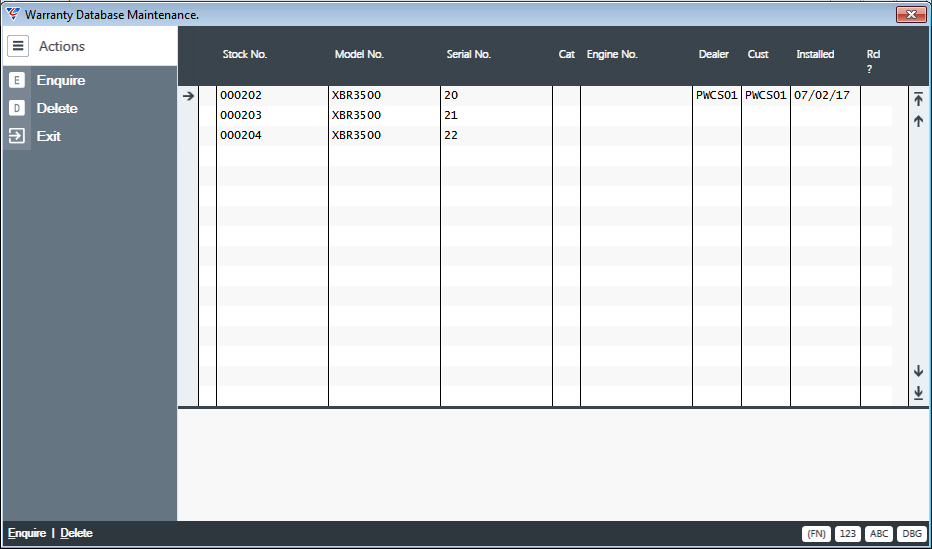

After completing the material issue, for serial tracked items, the system has automatically updated records in the Warranty Tracking Module.

Go to Warranty Tracking > Maintain > Warranty Maintenance, click on the View button and enter the item number in the fields provided.

The item just issued has additional “installation” information:

Enquire on the record just issued to view the updated warranty record for the item:

Receive the Service Exchange item from the Customer

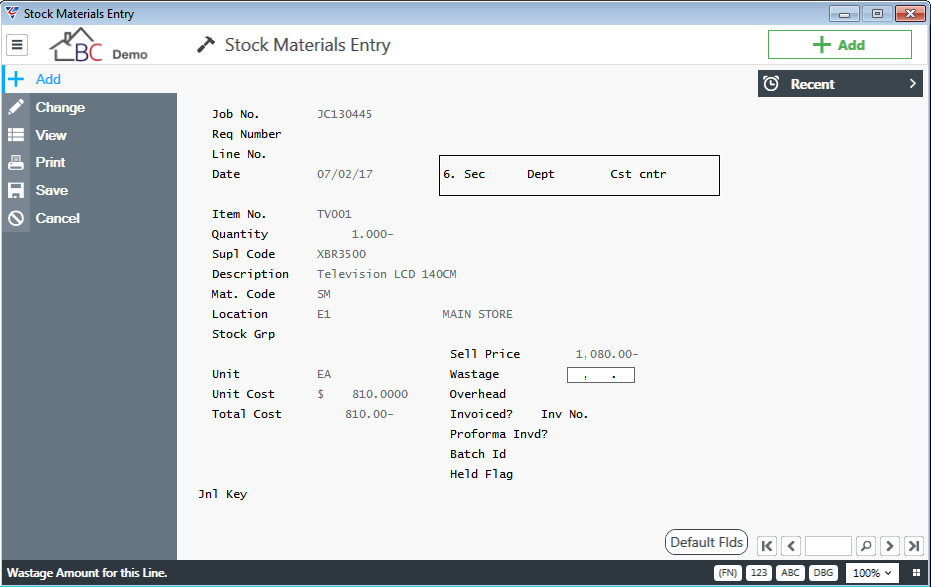

When the Service Exchange item arrives from the customer, record its receipt in the system. Go to Job Costing > Transactions > Cost Entry > Job Materials Cost Entry and record a Material Issue for the item received but enter the quantity as a negative:

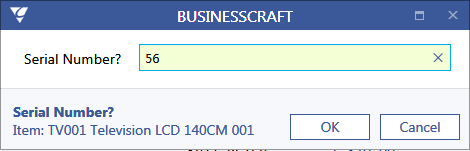

On save and exit, if the item is serial tracked, a prompt requests the serial number for the item received from the customer. For this example, we will enter serial number 56:

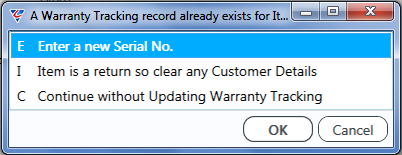

This serial number is not known to the system (it was supplied prior to warranty tracking being implemented) and the system prompts for which option to take:

There are now no costs on the job but there are two transactions processed which balance each other out.

Repairs can be carried out on the job and charged to the customer in the usual manner.

Inventory Status

On reviewing FIFO History in Inventory, serial number 20 is not in stock (it was sent to the customer) but serial number 56 is in stock having been returned by the customer:

Warranty Status

On review of the Warranty Tracking records, there is an additional record for serial number 56:

Click on the Enquire button on Serial Number 56 to view the detailed warranty record for that item:

Carry out the Repairs and Invoice

The repairs to the item received can be carried out, booking the costs on to the job and once repairs are complete, invoice the customer in accordance with the policies in place for Service Exchange repair work.

Revision 2

7th February 2017